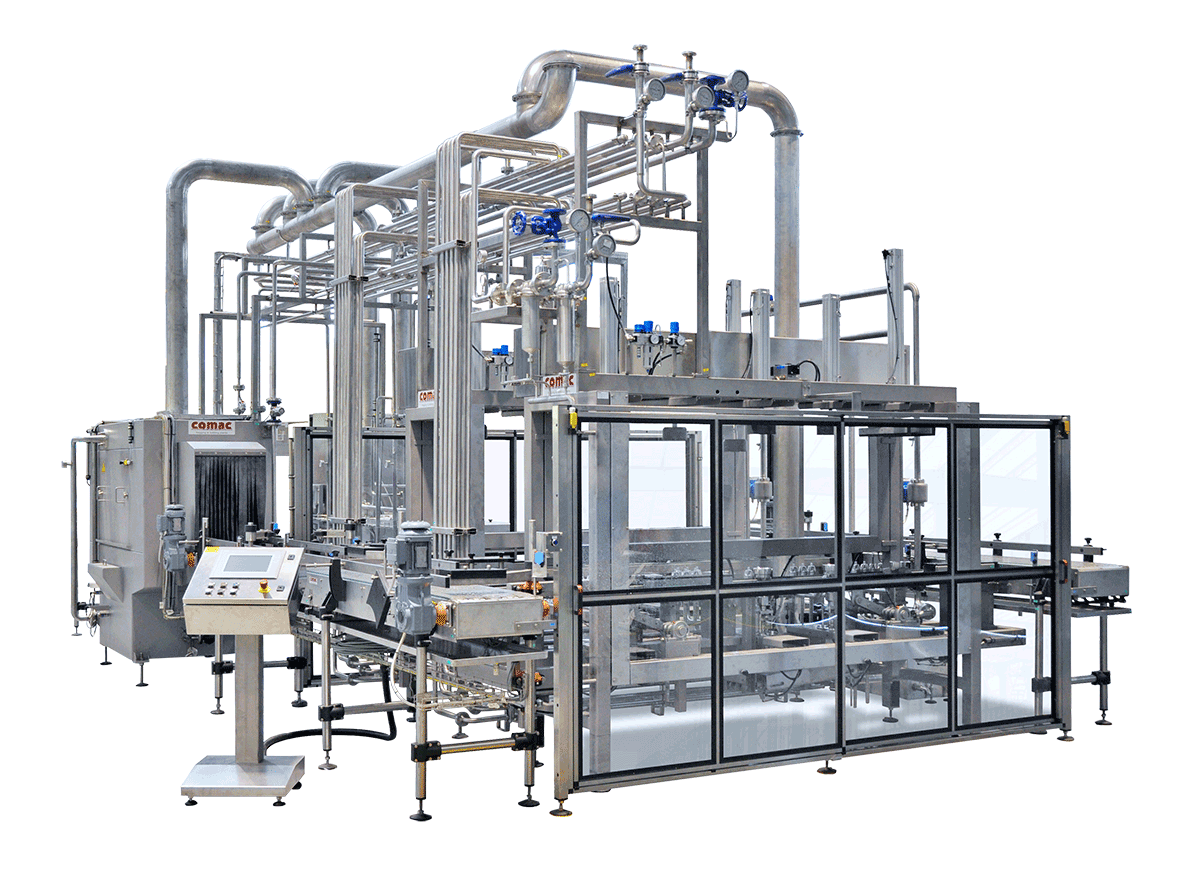

Comac Trieste K42 – 4+2T

Comac Trieste K42 – 4+2T

TRIESTE K42 is part of our range of automatic keg washer/fillers designed to perform washing and filling cycles automatically.

The technology and components used are the same as those used in the high production keg lines.

A PLC and an operator panel (HMI) allows the user to set and control all operation parameters.

The model TRIESTE consists of three washing heads, one caustic contact position, one steam contact position and one filling head and has got an output of approx. 60 to 70 KPH, depending on the keg size and washing cycle.

TRIESTE K42 is part of our range of automatic keg washer/fillers designed to perform washing and filling cycles automatically.

The technology and components used are the same as those used in the high production keg lines.

A PLC and an operator panel (HMI) allows the user to set and control all operation parameters.

The model TRIESTE consists of three washing heads, one caustic contact position, one steam contact position and one filling head and has got an output of approx. 60 to 70 KPH, depending on the keg size and washing cycle.

TRIESTE K42 is part of our range of automatic keg washer/fillers designed to perform washing and filling cycles automatically.

The technology and components used are the same as those used in the high production keg lines.

A PLC and an operator panel (HMI) allows the user to set and control all operation parameters.

The model TRIESTE consists of three washing heads, one caustic contact position, one steam contact position and one filling head and has got an output of approx. 60 to 70 KPH, depending on the keg size and washing cycle.